What they are, and how to start using digital twins to benefit your organization

Digital twins are a true representation of its physical counterpart. They behave exactly like the real thing and allow for realistic conditions to be achieved.

Digital twins bridge the credibility gap that basic simulation leaves. While basic simulations can get you a quick answer to a question, or an overview of results, they are limited to a scenario based on predefined metrics. Digital twins allow for the visuals, physics, interface connections and behaviours all to be set. They run in real-time and are compatible with real system inputs and outputs.

The result is a more complete and accurate picture of how a system will behave, saving you costs and time both now and in the future. Digital twin technology is helping to improve the sustainability of business in the Industry 4.0 age.

Digital twins can support your activities across the entire life-cycle of a project or system. They provide a safe environment for testing and experimenting. Use digital twins for:

Demonstrating your solutions to your customers and make clear decisions with confidence.

Experimenting with ease while working with prototypes, upgrades and retrofittings.

Increasing efficiencies and quality of your final solution by doing exhaustive tests and optimizations.

Reducing down time of your existing systems by testing any modification in advance.

Training operators and maintenance staff in a safe environment.

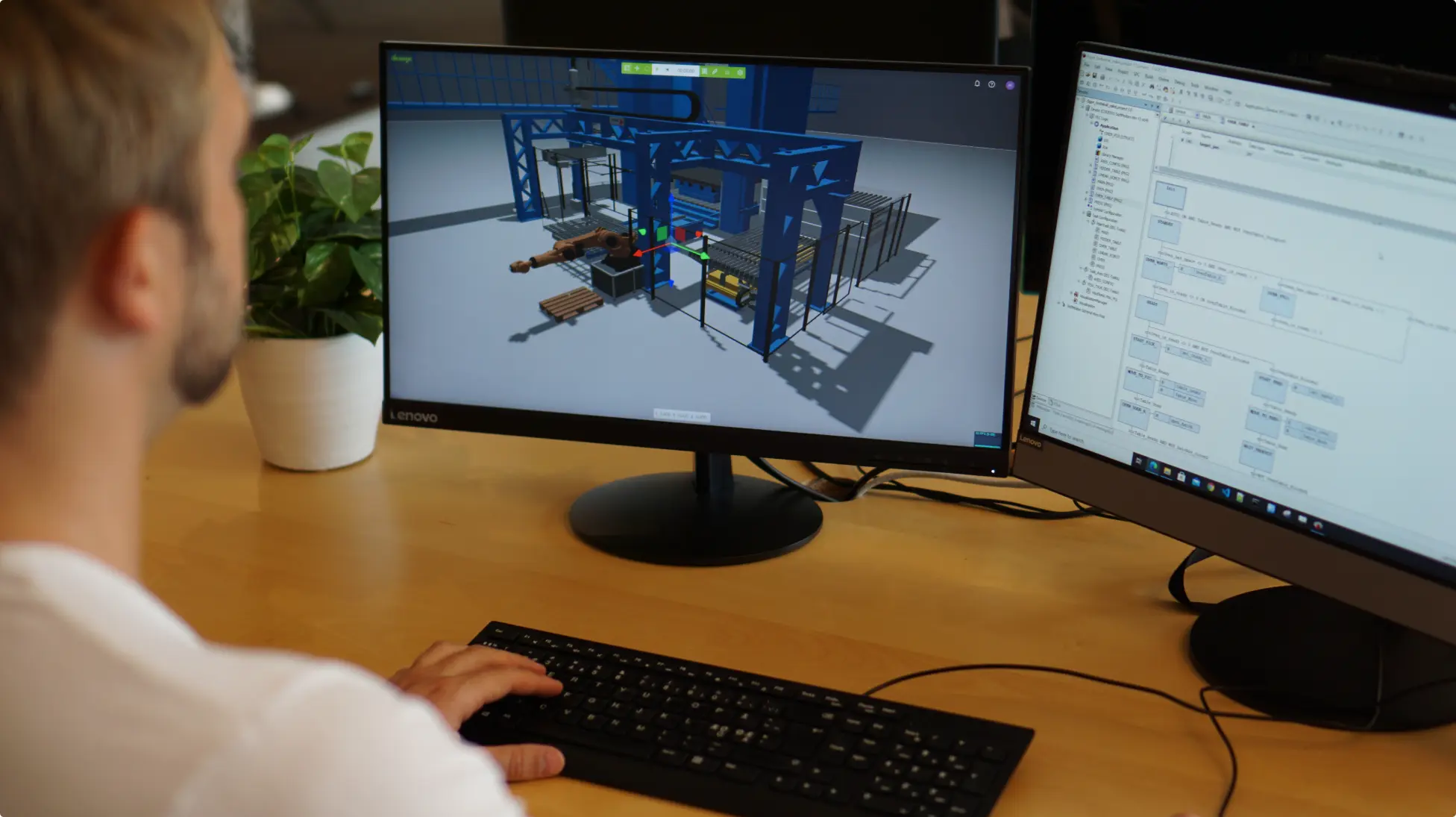

In industry, engineering and manufacturing digital twins can be used for virtual commissioning. Virtual commissioning is about carrying out the commissioning process of an industrial automated system with a digital twin, instead of the real thing.

In addition, its goal is to validate and verify the system early on. Virtual commissioning doesn’t replace the real thing, but it does reduce the time of real commissioning and its pain points. Above all, you can reduce the risk of errors and faults, whilst saving time, money and resources.

As a result, this can give you a competitive advantage and an ability to deliver high quality solutions.

Virtual commissioning and digital twins are not just for industry. For example, the benefits can be applied to many areas including healthcare, logistics and life science. In addition, digital twins can provide unlimited benefits even used in education. The key is finding the right solution based on your goals.

Simumatik’s emulation platform equips you with the necessary tools tounlock a modern workflow featuring Industry 4.0 capabilities. It’s easy toget started, granting you the power to create modular systems that canbe expanded, modified, and integrated as your needs evolve.

Digital twins, used in parallel (Collaborate), use it to demonstrate concepts in a convincing way, train operators, VR,off-line programming, connect third-party software.

At Simumatik, we offer personalized consultancy services to professional organizations, utilizing our 15 years of experience in virtual commissioning and digital twins.

Go to our consultancy services page for more details on our approach, and key stages working with organizations.

Discover