Our collaboration with Bosch BGSW aims to bring DeviceBridge to life through a digital factory demonstration, providing a tangible look into its functionality and impact.

BGSW: Pioneering IoT Solutions Worldwide

Bosch Global Software Technologies Private Limited (BGSW) is a wholly-owned subsidiary of Robert Bosch GmbH. It stands as a prominent global supplier of technology and services, providing comprehensive Engineering, IT, and Business Solutions.

With a widespread global presence encompassing the US, Europe, Japan, China, and the Asia Pacific region, BGSW leads in the design, development, and implementation of Internet of Things (IoT) ecosystems. Their expertise spans the entire spectrum of IoT, including Sensors, Software, and Services, positioning them at the forefront of this transformative technology.

Bringing Bosch’s DeviceBridge to Life in a Digital Factory

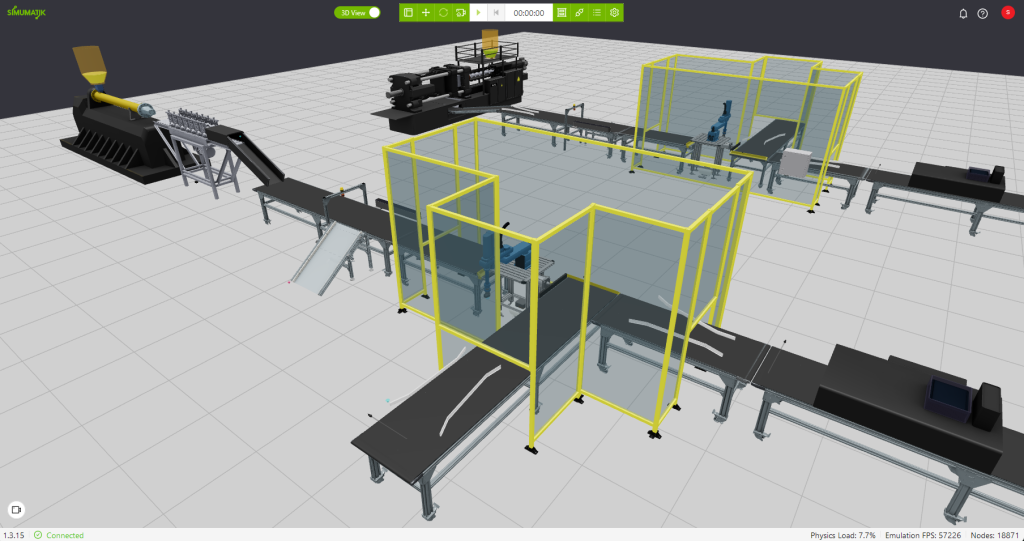

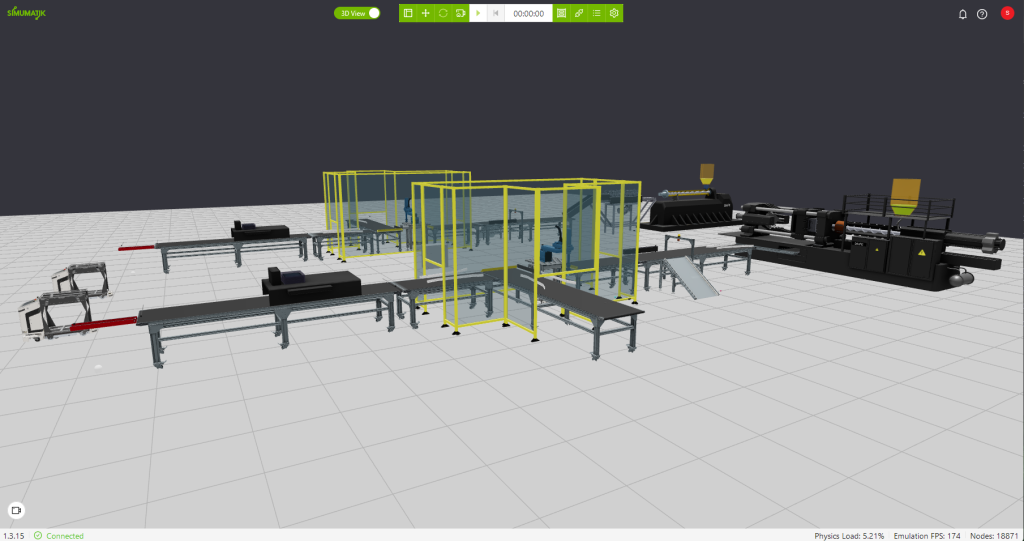

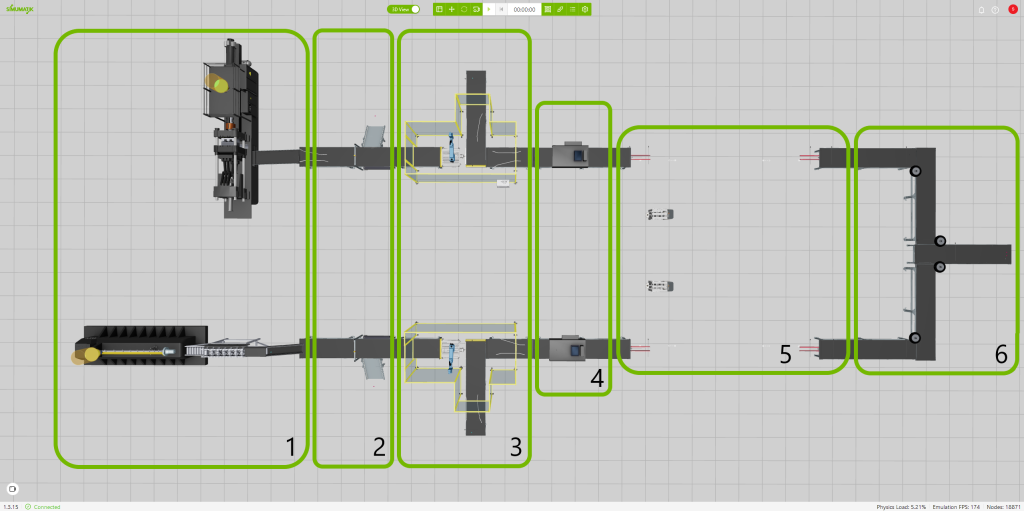

Bosch’s introduction of DeviceBridge marks a significant leap forward in manufacturing technology. To illustrate its potential, we’ve embarked on a project to construct a digital factory. This virtual setup replicates a real-world manufacturing environment, complete with production areas, quality inspection stations, SCARA robots for packaging, and self-driving vehicles for seamless transport. This setup combines a 3D visualization of the production line with the real-time data monitoring utilizing Bosch DeviceBridge.

The layout of the digital factory included the following stations:

- Part manufacturing by injection molding and extrusion

- Quality control stations

- Pick-and-place packaging stations

- Lid sealing stations

- Transportation with Active Shuttle AGVs

- Buffering area

Collaboration and Integration

In collaboration with BGSW, our team has combined expertise and practical insight to design and create a simulated manufacturing process. Working closely with Bosch’s engineers, we’ve developed a setup that closely mimics real-world operations, showcasing DeviceBridge’s capabilities of collecting machine data across various stages from part manufacturing to quality control, packaging and transportation.

Real-Time Insights and Analysis

The digital factory is controlled by an emulated PLC powered by Siemens’ control system, specifically TIA Portal and PLCSIM Advanced. DeviceBridge seamlessly communicates with the emulated PLC to collect real-time data from the factory operations. This data is then analyzed to provide valuable insights into factory performance.