Ohio University’s Journey Towards Industry 4.0

Ohio University, supported by a grant from the U.S. Economic Development Administration, is actively developing its curriculum to align with the ongoing Industry 4.0 revolution. Through the integration of new technology and tools, the university aims to provide students with cutting-edge educational experiences that prepare them for the evolving demands of the industry.

Adapting to Industry 4.0

Ohio University encountered the challenge of updating its engineering curriculum to embrace the principles and technologies of Industry 4.0. This involved revising traditional teaching methods and incorporating emerging technologies to ensure students were equipped with the skills needed to thrive in a rapidly evolving engineering landscape.

Collaboration with Simumatik

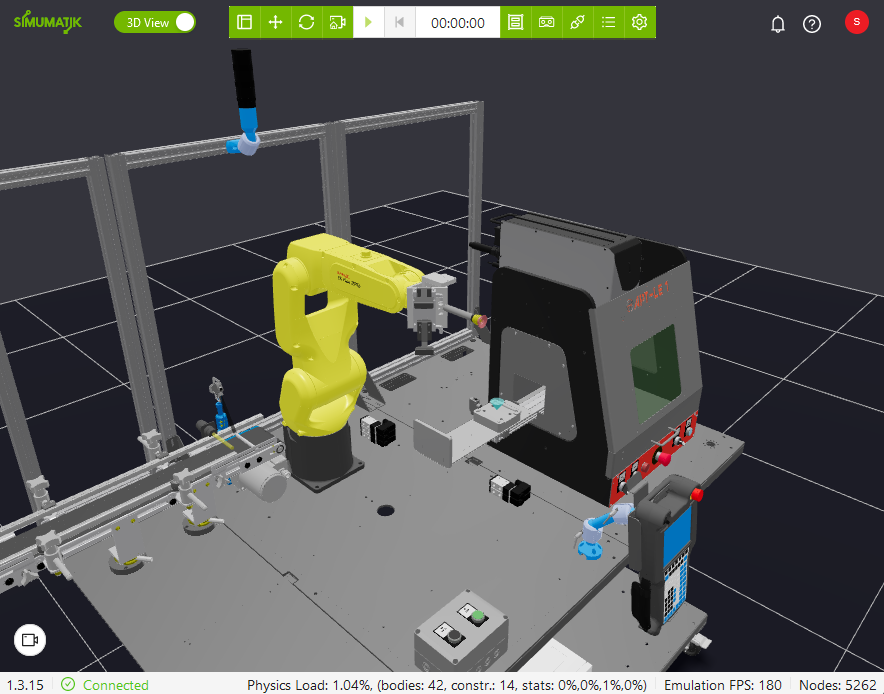

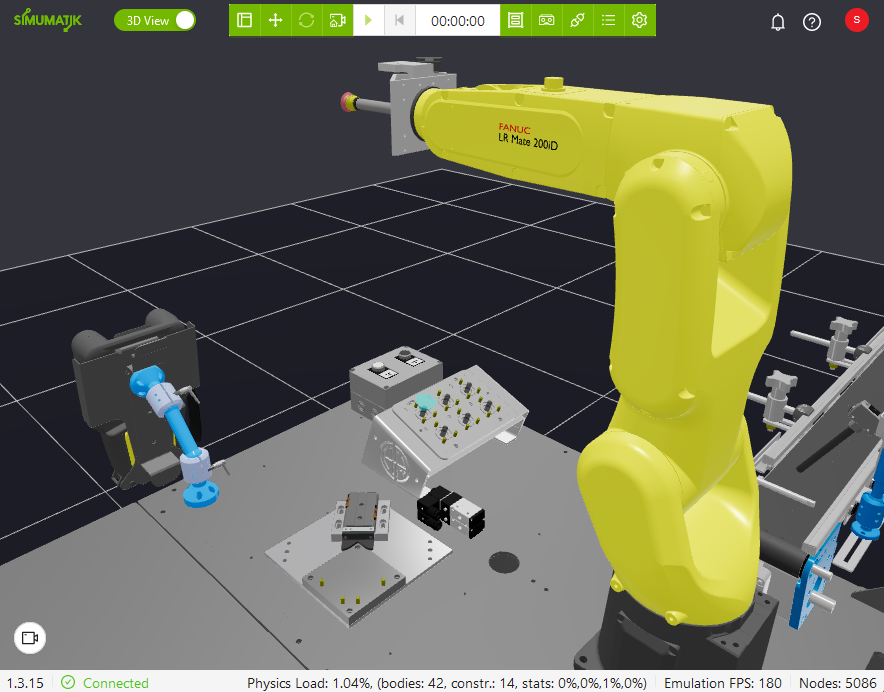

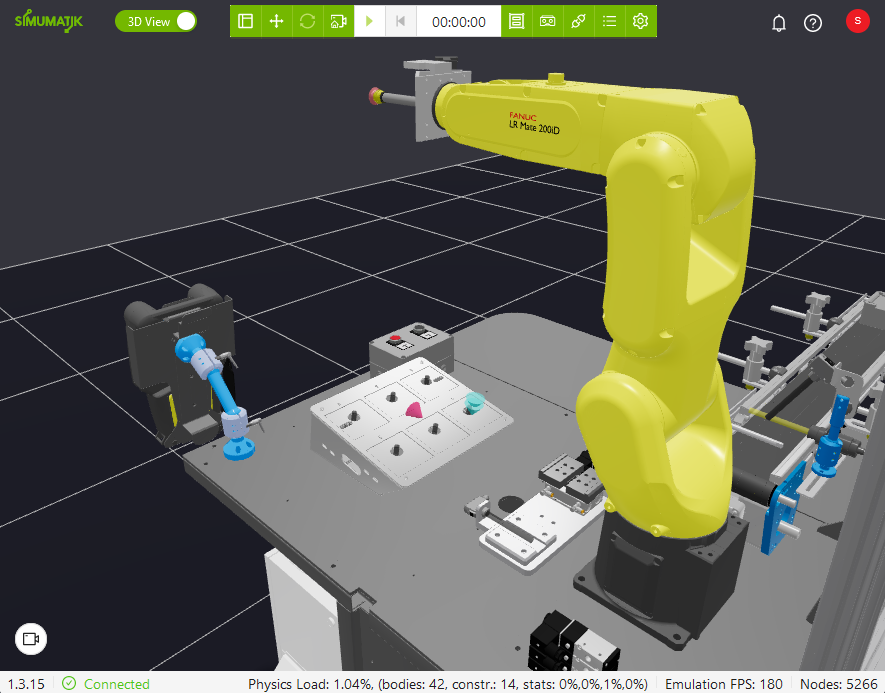

Ohio University partnered with Simumatik to develop a “Virtual smart factory” using digital twin technology. This collaboration allowed the university to integrate advanced simulation tools into its courses, providing students with hands-on experience in mechatronics, PLC, and robot programming.’

Enhancing Educational Offerings

The partnership between Ohio University and Simumatik brought to life the “Virtual smart factory” concept, enhancing students’ educational experiences significantly. This innovative approach has empowered students to gain hands-on practical skills and knowledge in cutting-edge Industry 4.0 technologies.

Key Achievements

- Improved Student Engagement: The integration of digital twin technology has enhanced student engagement and learning outcomes in mechatronics, PLC, and robot programming courses.

- Real-world Relevance: By simulating real-world manufacturing environments, students have gained valuable insights into Industry 4.0 concepts and applications.

- Access to Advanced Tools: The integration of digital twin technology has expanded students’ access to advanced engineering tools and simulations, empowering them to explore complex concepts and experiment with cutting-edge technologies that may have been less accessible in traditional educational settings.

Empowering Tomorrow’s Engineers Through Innovation

Ohio University’s collaboration with Simumatik to develop a “Virtual smart factory” represents a significant step forward in engineering education. By embracing digital twin technology, the university has provided students with practical experience in mechatronics, PLC, and robot programming, preparing them for the demands of Industry 4.0.

This partnership not only enhances student engagement but also reflects Ohio University’s commitment to innovation and excellence in education. Moving forward, the integration of digital twins will continue to play a vital role in shaping a curriculum that is adaptive and industry-aligned.