Remote Virtual Commissioning for a Heavy Vehicle Engine Manufacturer

In summer 2025, Austrian automation supplier Fill delivered an expansion

to an existing production line for a leading heavy vehicle engine manufacturer in Sweden.

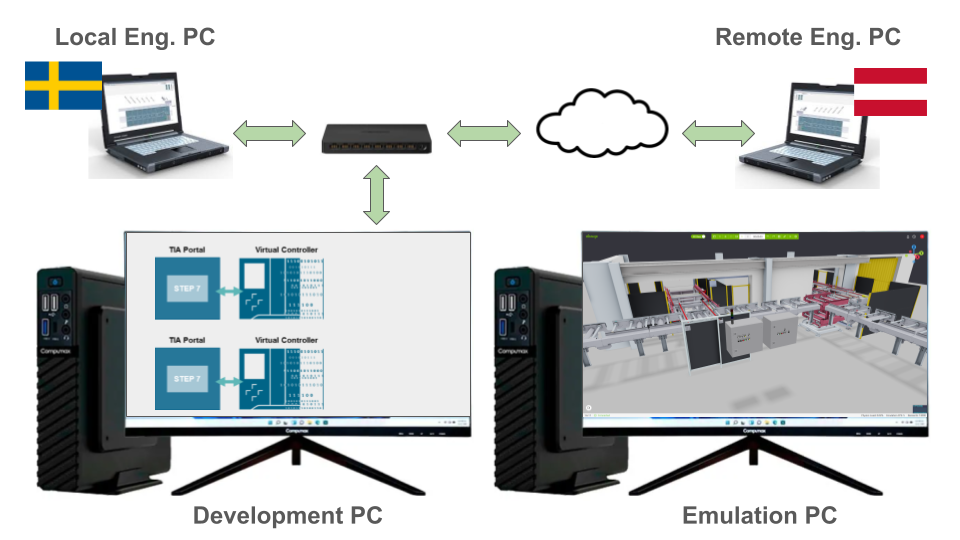

To ensure a seamless and low-risk integration, the project adopted a remote-first Virtual Commissioning (VC) approach powered by Simumatik.

This strategy enabled engineering teams from different countries to collaborate entirely at a distance, significantly reducing travel and on-site requirements while improving testing flexibility and overall system reliability.

Project Goals

The main goal was to enable remote engineering and collaboration between Austria and Sweden.

- Reduce travel costs and on-site testing time for the suppliers. Allowing the integration of the new production line with minimal disruption to existing operations.

- Validate the complete solution before hand by the end customer, including PLC logic, HMI screens, and interfaces.

Given the size of the products, a key factor was also to safely simulate heavy equipment behavior in a virtual environment, minimizing potential hazards.

How the Remote VC Was Executed

With support from Simumatik, a full emulation model of the production line, covering both the existing and new sections, was built using CAD data supplied by Fill.

The setup included:

- Two PLCSim Advanced instances to simulate the legacy and new PLC.

- A simulated PN/PN communication bridge via Simumatik’s communication layer

- Remote access for Fill engineers to program, test, and validate from Austria

- Testing of both manual and automatic operating modes using operator panels and HMI screens connected to the PLCs

Results

The digital twin enabled the team to thoroughly test the automation system before deployment.

This proactive approach helped identify potential issues early, optimize workflows, and reduce commissioning risk.

It also laid the groundwork for future process innovation, all without disrupting existing production.

One of the key advantages of this digital twin approach is its ability to test new production logic without touching the physical equipment, simply by preloading and simulating changes in the PLC.

Conclusion

This project showcases how Simumatik’s emulation platform enables fully remote, high-fidelity Virtual Commissioning.

By enabling real-time collaboration across borders, it reduced integration risk, boosted engineering flexibility, and shortened commissioning timelines.

The success of this distributed approach sets the stage for future remote upgrades,and demonstrates the power of combining automation with digital transformation.